Engineering partners with GM to produce device to make protective masks more comfortable for health care providers

Lipscomb engineering is leading the way in serving the community by making devices to bring comfort to health care providers.

Kim Chaudoin |

Lipscomb University's Raymond B. Jones College of Engineering has partnered with General Motors to use 3D printer technology to produce a device to make wearing protective masks more comfortable.

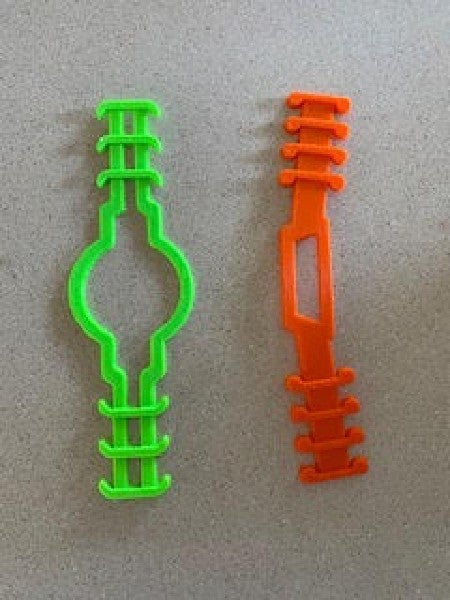

A representative from the GM plant in Spring Hill, Tennessee, located just south of Nashville, approached representatives from Lipscomb’s College of Engineering last week to ask if the university could use its 3D printers to make “ear savers” for masks for essential employees. GM has two designs (pictured below) for the ear savers — one standard device and another one that accommodates pony tails.

For doctors, nurses and other first responders who wear face masks for a prolonged period of time, an ear saver is a small plastic part that can provide a lot of relief. The device goes behind the person's head and has small hooks on it for the elastic bands of a face mask to wrap around, taking pressure off the ears and putting the stress on the back of the head instead.

Lipscomb engineering is manufacturing two types of ear savers using 3D printing technology.

Lipscomb’s College of Engineering has been producing these devices for about four days. This week, they created nearly 400 devices and about 300 were delivered to GM, who is donating them to health care providers at Maury Regional Medical Center in Columbia, Tennessee, and others in the area. The Lipscomb engineering team will continue to produce ear savers in the workshop in the Fields Engineering Center six days a week for the foreseeable future.

In addition, Lipscomb engineering faculty have also been hard at work for several weeks producing free protective face shields for Middle Tennessee medical providers. Face shields are personal protective equipment devices that are used by many medical workers for protection of the facial area from the body fluids of a patient. With production starting in the last week of March in Lipscomb’s Fields Engineering Center, they have produced more than 2,000 face shields so far. Since March 28, more than 1,800 have been distributed free to a number of medical sites or individual health care workers in Davidson, Williamson and Maury counties including Southern Hills Medical Center, Williamson County Medical Center, Saint Thomas Medical Center and Nashville’s Siloam Health clinic for underinsured patients. More information is available here.

The directors of Lipscomb’s Peugeot Center for Engineering Service in Developing Communities in the College of Engineering, Steve Sherman, executive director, and Caleb Meeks, director of operations, along with Samuel Wright, the college’s engineering laboratory manager, are the core team producing the ear savers and plastic face shields.

READ MORE: Engineering college fabricates free face shield for health care workers