Donated wind tunnel to be in operation in 2021

The new device and senior design project will bring advanced real-world learning opportunities for future students

Shelby Bratcher and Janel Shoun-Smith |

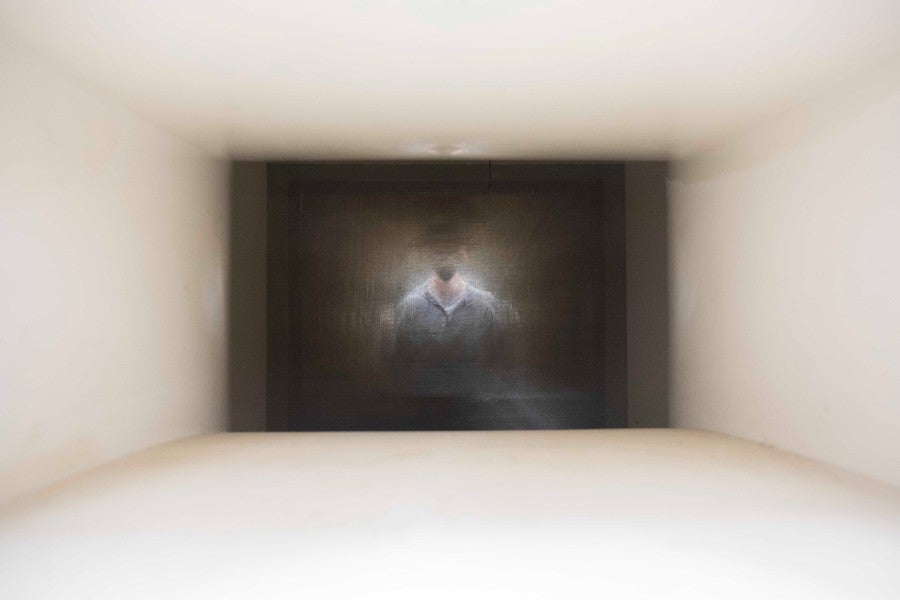

Senior design team leader Paul Kurtz looks over Lipscomb's wind tunnel, donated from Jacobs and housed in the parking garage behind the Fields Engineering Center.

Thanks to the generosity of international engineering firm Jacobs, and the hard work and skill of seven senior mechanical, electrical and computer engineering students, by next year Lipscomb engineering students in all disciplines, as well as aspiring engineers in Nashville’s high schools, will have new opportunities to use an on-site adaptive wall wind tunnel to test design models.

The wind tunnel, housed in a customized lab in the new north parking garage behind the Fields Engineering Center, will set Lipscomb apart from other colleges’ engineering programs, expand student and faculty research opportunities and provide Lipscomb students with greater capacity to test prototype models and conduct more advanced experiments.

As their senior capstone project, seven senior engineering students, along with electrical and computer engineering Chair Greg Nordstrom, are spending the 2020-21 school year installing the wind tunnel and its computer data acquisition system as well as ensuring its safe and effective operation.

The wind tunnel design team is excited to be part of a project that isn’t just doing design and conceptual work, but involves hands-on installation, said Paul Kurtz, an electrical engineering major from New Hartford, Connecticut, who is serving as the team leader. The project is a great example of the real-world teamwork students experience in all senior design projects, but also brings both mechanical and electrical engineers together to collaborate, something that doesn’t happen very often, said team member Jesse Johns, an electrical engineering major from Nashville.

The wind tunnel's main testing area includes walls that can be moved to adapt to the size of the model being tested.

The Wind Tunnel

The wind tunnel, donated by Jacobs in 2019, will be used for predictive testing. Models of cars, planes or machinery parts can be tested to see how they change, bend or break based on their shape under the influence of air flow. Currently students use a tabletop-sized wind tunnel available in the fluids lab to demonstrate surface flow.

The wind tunnel is expected to heighten student interest in specific engineering fields, increase student retention, provide more active learning opportunities for underclassmen and advance students’ opportunities in graduate school and industry jobs, among other benefits, said College of Engineering Dean David Elrod.

Powered by a 40 hp fan, the Jacobs wind tunnel was originally used for scale model testing of passenger cars and racecars and for wind tunnel technology development, said Steve Arnette, senior vice president at Jacobs.

The adaptive walls of the wind tunnel allow the device to change the size of the testing area and thus accurately simulate real-world aerodynamics in the laboratory. In addition to testing for cars, this wind tunnel can also be used to study and test the aerodynamics of other scaled models such as motorcycles, aircraft, flying drones and other aerospace vehicles, he said.

Through the use of the college’s innovation lab, which includes four 3D printers, Lipscomb students have the capability to build models, print them in 3D printed materials, and immediately test them in the tunnel. Students in Lipscomb’s competitive engineering design teams, which are or have created a rocket, aircraft, concrete canoe, steel bridge and all-terrain vehicle, could all make use of the wind tunnel to test prototypes and refine their designs.

In 2019, Jacobs Engineering Group, an international technical, professional and construction services firm with operations in Tennessee, sought to strengthen its relationships with local universities by providing opportunities for hands-on education and research through donating the wind tunnel, worth $750,000, to a university in the Southeast, said Arnette.

“Lipscomb University submitted a very comprehensive proposal, explaining their plan and outlining ways to further enhance the two-way relationship between Lipscomb University and Jacobs Engineering, which spans two decades,” Arnette said.

Incorporation of the wind tunnel will allow Lipscomb to dramatically enhance not only its undergraduate educational programs but also its STEM outreach to a diverse future generation of engineers, said Elrod, a former engineer at Jacobs.

“We focus on developing highly skilled engineers through the use of project-based learning inside and outside of the lab,” Elrod said. “These projects are not the standard cookie-cutter lab with prescribed steps and predetermined outcomes. We believe that connecting theory to real-world design problems increases learning outcomes and helps with student retention. Access to a wind tunnel on campus allows us to do just that.”

The wind tunnel will enhance Lipscomb’s potential research opportunities in product development for automotive secondary markets, studies for the racing industry and basic research in aerodynamics, Elrod said.

It is already providing Lipscomb’s electrical and computer engineering students opportunities to conduct research in data acquisition and controls, measurement and instrumentation, image processing and facility automation through the ongoing senior design project, Elrod said.

“We will seek out and encourage collaboration on a variety of aerospace and automotive topics,” Elrod said. “As a member of the Tennessee Space Grant Consortium, comprised of 15 colleges and universities and two non-profit organizations, Lipscomb can serve a unique role in encouraging aerospace research in the Middle Tennessee Area.”

One of the jobs of the senior design team is put the four parts of the wind tunnel together and to properly vent the air from the device.

The Senior Design Project

Seniors Kurtz, Johns, Jaden Bowen, Leo Alvarado, Nathaniel Boggus, Jack Ardor and Ethan Dupuis are already reaping the educational benefits of the wind tunnel as their senior design project has particularly high real-world stakes and provides unique job experience.

“This is important because there are real outcomes if it doesn’t happen. It is an expensive wind tunnel that has to be done right,” said Dupuis, mechanical engineering major from Saco, Maine.

Most of the senior design projects are intended to require students to collaborate on a design from start to finish, but in this case, these students are experiencing a project that must go from start to finish in three different disciplines, said team members: the mechanical aspect of putting the wind tunnel back together in its new space, the electrical aspect of hooking the device up to its operational controls in an adjacent room and the computer aspect of acquiring the data and making it usable for students of the future.

According to team advisor Nordstrom, the student will need to design fittings and couplings to put the four pieces of the wind tunnel together, manufacture their own ducting to vent the air out into the parking garage during operation, create electrical safety systems (such as an automatic cutoff switch) to operate the tunnel safely and set up the data acquisition hardware to read the data.

The Louis R. Draughon Foundation is providing several data acquisition chassis for the project as part of an annual gift of equipment the foundation has provided to the college for decades.

Team members are required to dedicate 10 hours of work each week to the project, but it seems like the work never ends, says Kurtz. The students had to work with the civil engineering faculty and students to pour a new concrete floor in the space to make the floor level for proper operation. Ardor, mechanical engineering major from Franklin, North Carolina, is in charge of designing all the needed parts through computer aided design software, and Dupuis’ job is to create tests to ensure the tunnel is producing accurate results for the benefit of future students.

“I’m hoping employers will see this on my resume and say, ‘Hey, they take their engineering seriously at Lipscomb,’” said Johns.

“In addition to the valuable real-world experience this project will provide for me in my future career, it’s exciting to be working on something that we know will impact the education and future of engineering students for years to come,” said Kurtz.

Senior design team leader Paul Kurtz is a ghostly presence as seen through the end of Lipscomb's new wind tunnel.